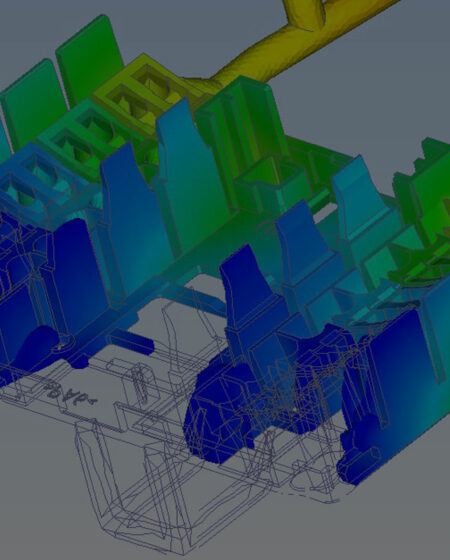

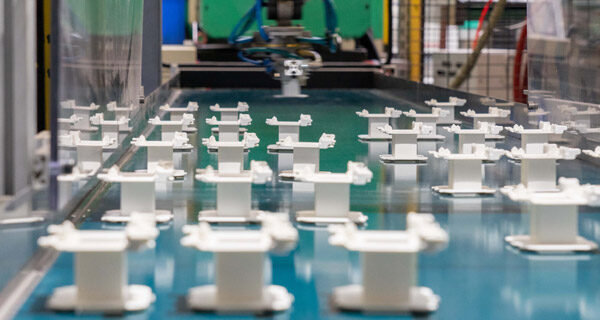

We at Peiler & Klein Kunststofftechnik GmbH are your reliable experts for high-quality injection molded parts made from a large number of different standard and special types of plastic, such as high-temperature materials or radiation-crosslinked materials. In addition, we also have a deep knowledge and experience in working with bio-based materials from natural resources. In this field we work on development projects with renowned industries and universities.

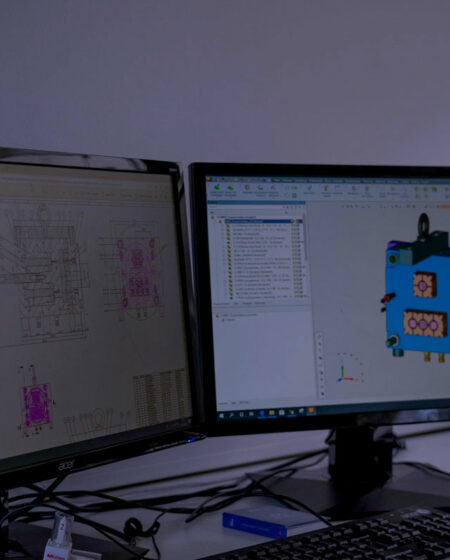

Our long history and experience in designing and building injection molds gain us trust and long-term relationship with our customers.

Markets we serve: automotive, industry, aviation, cosmetics and medicine.